ART OF SUSPENSION

ABOUT RACINGBROS

SAFETY FIRST

The safety of athletes is our top priority. Each system is carefully engineered to provide maximum safety, no matter where or how you ride.

UNMATCHED CONTROLLABILITY

With over 30 years of expertise and innovative technology, RACINGBROS delivers precise handling and responsiveness to help you push boundaries with confidence.

PEAK PERFORMANCE

Built with premium materials and advanced engineering, our suspensions deliver exceptional durability and performance on both racetracks and trails.

PERSONALIZED EXPERIENCE

Every ride is unique. RACINGBROS provides tuning and customization options to suit your style and preferences.

CERTIFICATIONS

ISO 9001:2015

R&D, manufacture and sales of suspension

IAF Code: 17

Certificate No.: ARES/TW/I2312175Q

QUALITY ASSURANCE

At RACINGBROS, quality drives performance. Every suspension component is precisely engineered and tested through strict multi-stage controls to ensure durability and reliability — on the street, trail, or racetrack.

Incoming Inspection

Manual Parts Cleaning

Axle Assembly

Bearing Assembly

Hand Squeeze Test

Pressure Filling

Automatic Hydraulic Oil Filling

Damping Component Assembly

Outer Shaft Assembly

12-Hour Stabilization

Labeling

Packaging

Every Component Counts

To ensure peak performance, each part of our shock absorbers is precisely measured and matched. Integrated valving pistons are assembled with exacting tolerances to deliver consistent and responsive damping.

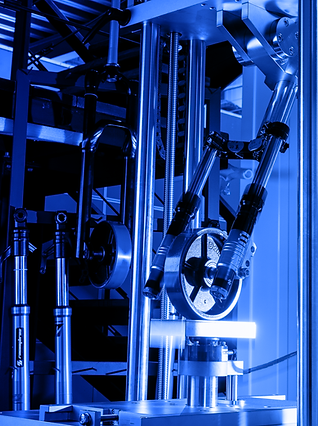

Force-Displacement Testing

All suspension units undergo advanced force-displacement testing to analyze spring rate curves and dynamic response. Performance is validated post high-pressure nitrogen charging to ensure optimal behavior under load.

Durability & Finish Validation

Using specialized durability machines, we simulate real-world mechanical stress and verify surface coatings. This guarantees long-term reliability, corrosion resistance, and consistent performance in the harshest conditions.